Picture a warehouse where materials, workers, and equipment flow seamlessly. Warehouse design not only maximizes space utilization but also affects company profitability by optimizing product flow. Or, if it’s overstock or seasonal goods, note temporary locations in your inventory management system so you can find it when needed. Inventory management is the umbrella term for the procedures and processes that affect ordering, receiving, storing, tracking and accounting for all of the goods a business sells. If you need additional help or clarification on any of the inventory management strategies discussed here, feel free to reach out to us.

- With automation, businesses can free up their staff to focus on other aspects of their operations.

- Tracking SKUs, barcode data, suppliers, and lot numbers enables businesses to accurately identify, track, and manage their inventory.

- Reorder points are specific to individual inventory items and are based on that item’s average daily usage, order lead time and the amount of safety stock you have on hand.

- With slower-shipping suppliers or seasonal purchases, you’ll have fewer and larger purchases, which ties up more cash in inventory.

- If you’re searching for ways to gain control of your inventory, look no further.

- By leveraging these technologies, organizations can optimize inventory management, reduce costs, and enhance overall productivity.

Enhanced forecasting accuracy

- Barcoding systems and mobile devices are the unsung heroes of inventory management.

- Inventory management is important to a wide range of businesses, including retail companies, shipping and logistics operations, and manufacturing businesses.

- Just-in-time (JIT) inventory management aims to maximize efficiency and lower costs by coordinating inventory arrival with the start of production.

- Conversely, LIFO assumes that the most recently acquired inventory items are sold first.

- A warehouse management system for small businesses isn’t merely a ‘nice to have’—it’s essential.

For these reasons, inventory management is important for businesses of any size. Knowing when to restock inventory, what amounts to purchase or produce, what price to pay—as well as when to sell and at what price—can easily become complex decisions. Small businesses will often keep track of stock manually and determine the reorder points and quantities using spreadsheet (Excel) formulas.

B. Stock-out rate

Lean Six Sigma combines the Six Sigma methodology with lean manufacturing to increase efficiencies within your inventory management process. For example, you may use it to streamline your process by eliminating unnecessary steps. Safety stock represents the amount of extra inventory you keep on hand to cover unexpected demand or delays in future deliveries. Safety stock is determined based on demand variability, delivery lead time, the cost of stockouts and the cost of holding inventory. Now that you are aware of all there is to know about dealing with inventory management problems, it is time to manage your store’s inventory effectively.

What is Supply Chain Management (SCM)? Everything You Need to Know

If you want to learn about the new trends in inventory management; how to manage inventory effectively in 2020 by using the right tools, strategies, and processes, this article is for you. Regardless of how complex your supply chain network is, there are some basic techniques that provide great overall solutions. Two areas to research and consider are how to manage your safety stock levels, and your individual supply and demand plans.

Effective Inventory Management Requires Short and Long-Term Attack Plans – Modern Distribution Management

Effective Inventory Management Requires Short and Long-Term Attack Plans.

Posted: Tue, 04 Oct 2022 07:00:00 GMT [source]

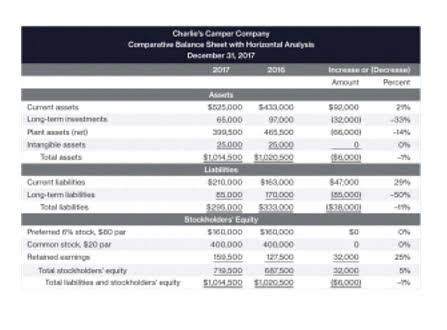

These raw materials undergo processing to produce the finished product, requiring effective production planning and management to optimize resources and minimize lead times. Inventory represents a current asset since a company typically intends to sell its finished goods https://www.bookstime.com/ within a short amount of time, typically a year. Inventory has to be physically counted or measured before it can be put on a balance sheet. Companies typically maintain sophisticated inventory management systems capable of tracking real-time inventory levels.

Together, these elements form the backbone of a robust international supply chain capable of withstanding diverse challenges. With data coming from various sources in different formats, ensuring uniformity becomes a daunting task. Deskera People is a straightforward tool for centralizing your human online store inventory resource management functions. Easyship offers fulfillment assistance and partners with 20+ warehouses around the world. Devices and vehicles can be provided with QR codes so that important information can be retrieved and various actions can be carried out where the devices/vehicles are located.

- It assumes that there is a trade-off between inventory holding costs and inventory setup costs, and total inventory costs are minimized when both setup costs and holding costs are minimized.

- Developing personalized customer interactions involves tailoring your communications and marketing strategies to individual customer preferences, behaviors and needs.

- Furthermore, a responsive supply chain enables companies to adapt quickly to changes in supply and demand, seizing market opportunities and gaining competitive advantages.

- By accessing vendors from various places or with diverse routes and ports, your business can decrease the risk of disruptions due to regional or global events.

- Here’s a seven-step approach to creating an inventory management plan with procedures, controls and tools tailored to your business’s unique needs.

- If you don’t have goods in stock to sell, or if you can’t find items to fill orders, you have no income.

- Minor discrepancies in receiving new stock can leave you scratching your head at the end of the month or year, wondering why your numbers don’t align with your purchase orders.

FAQs About Inventory Management

With automation, businesses can free up their staff to focus on other aspects of their operations. Automation also reduces manual errors and makes it easier to track inventory levels in real time. Proper inventory management can help reduce unnecessary spending on overstocked products, outdated items, and obsolete components, as well as decrease your safety stock inventory. However, it can be more time-consuming, expensive and complex than other inventory management techniques, such as periodic inventory management. With the periodic technique, inventory levels are only updated periodically rather than continuously.

Minimum order quantity (MOQ) and economic order quantity (EOQ) are two methods a business can use to determine when to reorder products. Understanding the broader picture of how items sell is essential to controlling your inventory. You should understand these items’ complete sales cycles – including how many you sell in a week or a month – and closely monitor them. Others do monthly, weekly or even daily spot checks of their hottest items. You might also consider tracking each item’s cost over time so you’re aware of factors that affect pricing, such as scarcity and seasonality. It’s a way of managing inventory that assumes that the last items you bought or produced are the first ones you sell.

Prioritizing Best-Selling Items

These rings are illicit businesses that operate in regions where regulation is weak and geopolitical upheaval has resulted in a high degree of lawlessness. Organize training sessions and workshops to introduce your team to your chosen CRM platform, its features and how it aligns with the overall business objectives. Encourage open communication and collaboration among team members to share best practices and address challenges during the CRM implementation process. Provide ongoing training and support to ensure your team members are comfortable using the CRM platform and maximizing its capabilities. Your team members will interact with customers and use the CRM platform daily, so getting their buy-in and ensuring they’re equipped with the necessary skills to implement and use the tool is essential.